Nitrification

OBJECTIVES

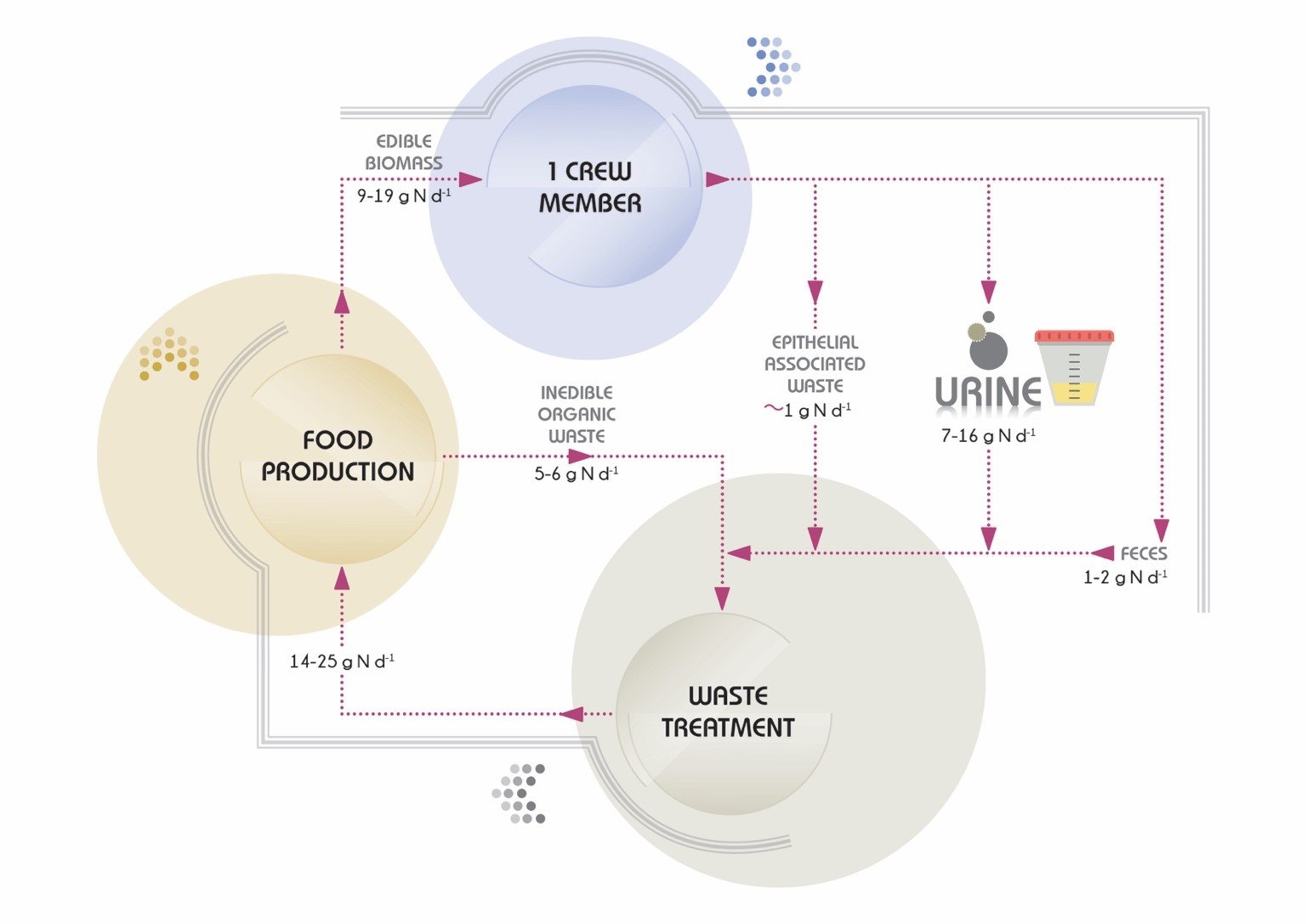

After Carbon, Nitrogen is the main elements to cycle. A crew member consumes 9-19 g protein-N per day, and excretes the same amount, mainly under the form of urea in urine (7-16 g N per day). Table X details four purposes of nitrification-based processes, ranging from stabilisation of waste streams to the production of useful compounds (i.e. nitrate, nitrogen gas and/or water).

Within the wastes, the main Nitrogen source is coming from Urine and it will lead to proteins production. To ease the Nitrogen, cycle several challenges have to be solved:

- Stabilisation of urine. To simplify urine shall not become a risk for the astronaut

- Transformation of urine in the proper substrate for higher plants and micro-algae cultivation

- Removal or transformation of any chemical elements which can be toxic for other MELiSSA processes.

Of course, all these challenges shall be solved with the best-set of ALISSE criteria: low mass, low energy, low risk, and low crew time.

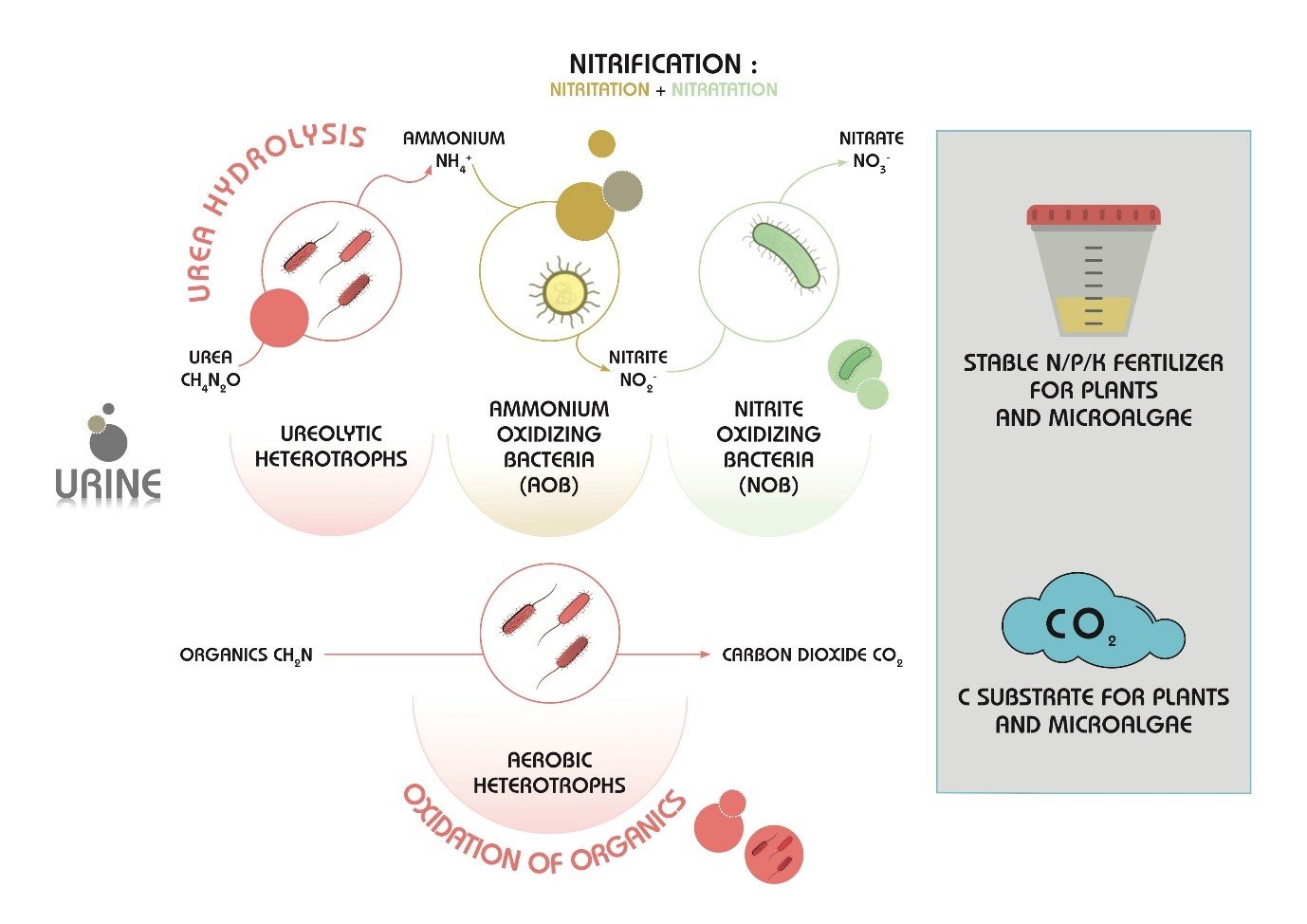

Within MELiSSA project, this Nitrogen transformation task is mainly performed by NITRIFICATION.

The progressive steps of Urine transformation are summarised in the figure below :

CHALLENGES AND APPROACH OF THE RESEARCH

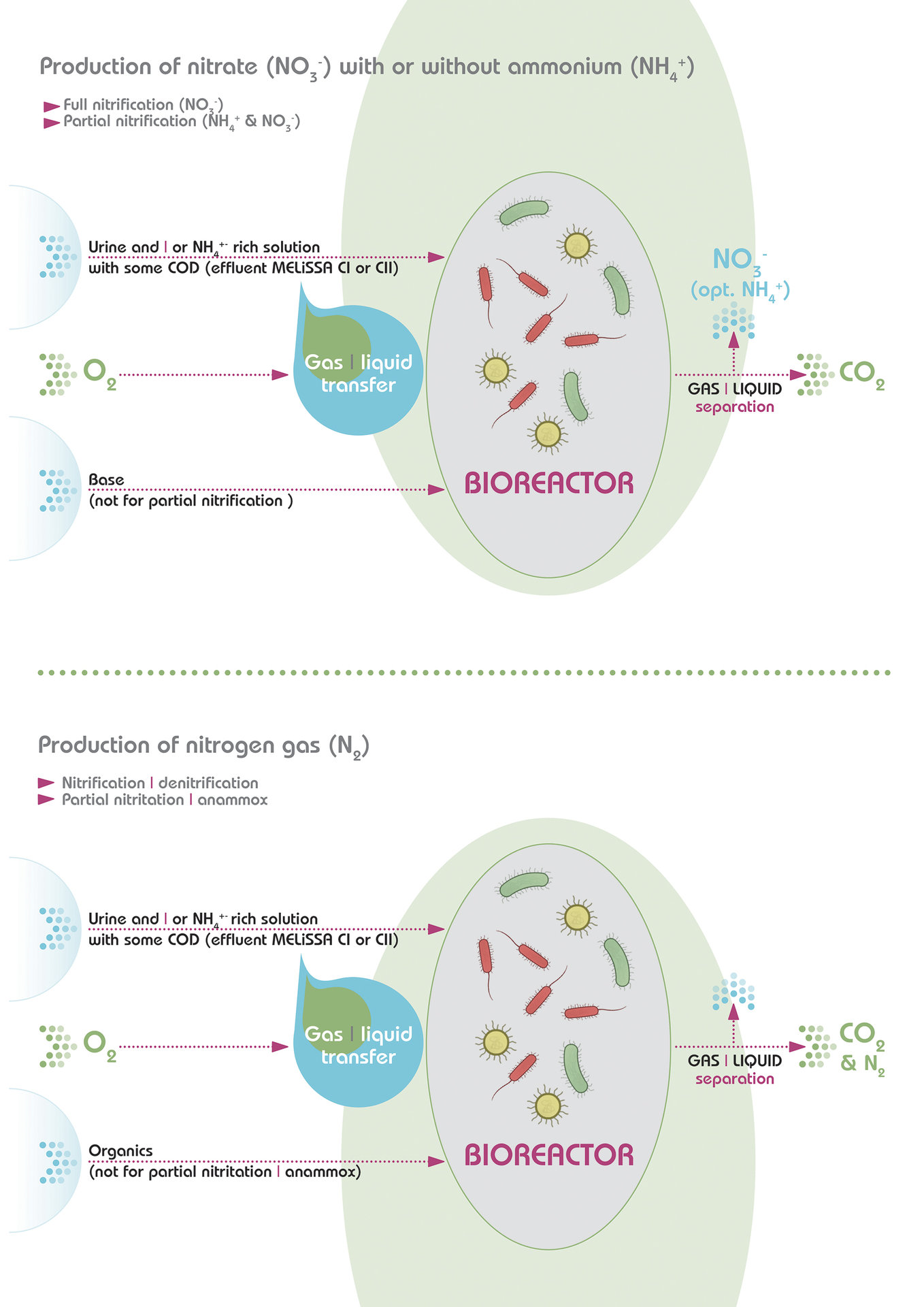

The first set of R&D challenges lies at achieving the best technological process performance, aiming for instance at nitrogen and carbon mass balance closure, while minimizing the mass (volume) and requirements (e.g. energy, chemicals) of the process.

Secondly, mechanistic understanding is important to achieve a reliable and predictable process. Therefore, two approaches are integrated with process technology, namely detailed characterization of the microbial conversions at the physiological and molecular level and mathematical modelling for process control, automation and integration with the other units in the treatment or production system.

In terms of space adaptation, the focus is oriented to understanding radiation effects and developing a gravity-independent system. For the latter, this implies a suitable gas/liquid transfer step to provide the necessary oxygen (O2) to the microbes, and a specific gas/liquid separation step to remove gaseous compounds from the process and the produced liquid.

FLIGHT EXPERIMENTS

Space environment had a few more constraints, mainly gravity reduction and space radiations.

Gravity will mainly affect the multi-phase issues: Gas/Liquid/Solid mixing and/orseparation. Radiations potentially affect the molecular level of the bacteria (e.g. DNA, RNA).

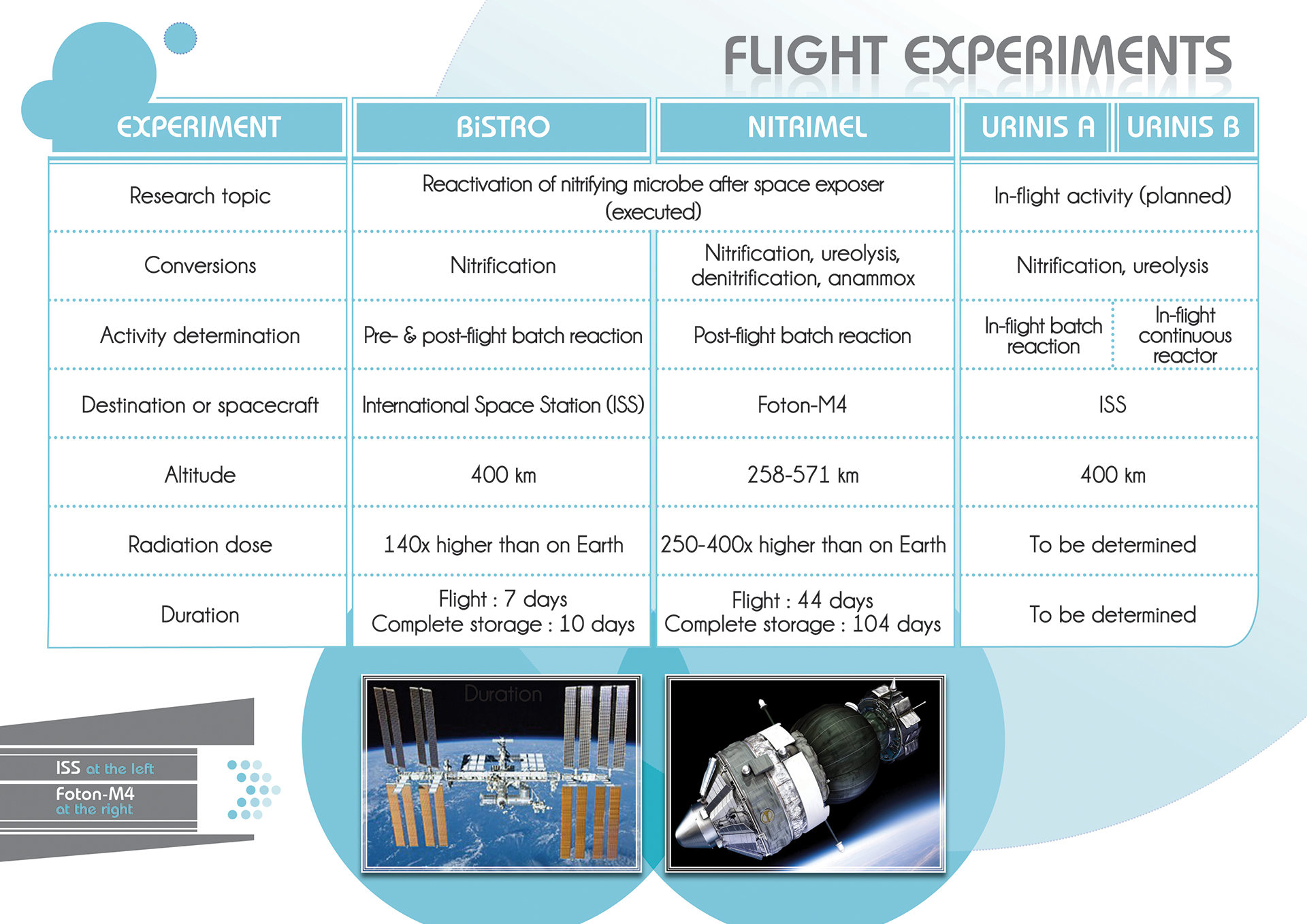

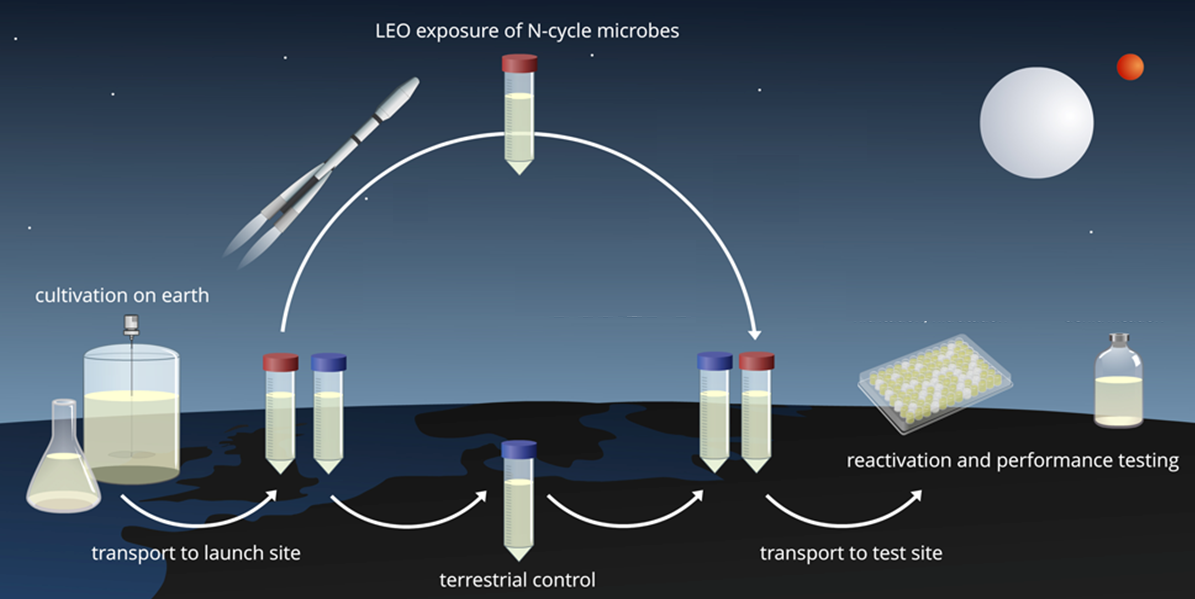

Within MELiSSA project two flight experiments (BISTRO and NITRIMEL) have been successfully performed. Two more are currently under preparation. The first two experiments demonstrated the reactivation potential of a microbial consortium, when exposed to elevated levels of radiation and fluctuating gravity. These findings are promising for all nitrification-based processes.

Nowadays, the challenge currently addressed in the preparation of the coming URINIS flights is to obtain in-flight activity in the international space station (ISS), both in batch incubations as in a first continuous reactor test. Figure below explain the logic of these experiments.

GROUND DEMONSTRATION ACTIVITY

Any space hardware has to be robust and efficient, but it is of course even more critical for a life support system aiming to maintain astronaut life.

Therefore, before any flight hardware development it is crucial to demonstrate the robustness of MELiSSA processes on ground.

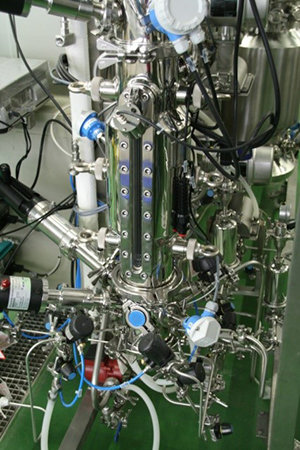

This demonstration started by an engineering phase, to study all the Nitrification requirements and design the relevant Nitrifying bioreactor.

In terms of aeration, sparging with air and oxygen has been shown, as well as gravity-independent membrane aeration. For effluent withdrawal typically a membrane is used, generating a bacterium-free stream.

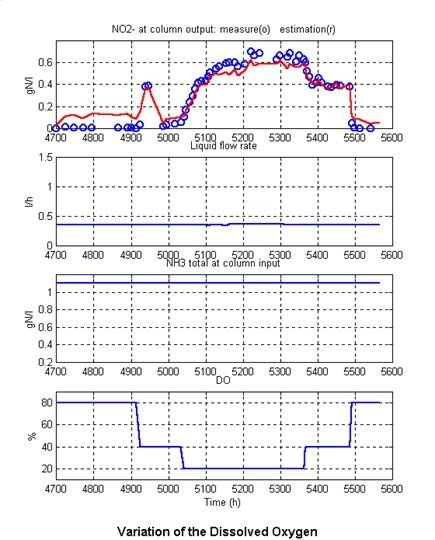

Besides validation of key performances, the effect of key parameters (e.g. oxygen, mixing, nitrites concentration...) has been studied, and a predictive control law was implemented (figure 3).

Demonstrates the quality of the mathematical prediction of Nitrites concentration (blue line) versus experimental analysis (red points), during piloted dissolved oxygen steps (e.g. 20% to 80%).

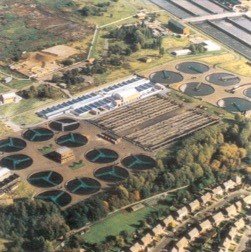

Long-term stability was demonstrated in the MELiSSA Pilot Plant in Barcelona for more than a year.

TERRESTRIAL APPLICATIONS

The research work on nitrification has yielded several terrestrial valorization examples.

In the early 1990s, ESA and the R&D center of Générale des Eaux, today OTV-VEOLIA, teamed up to study and compare physical support materials for nitrification in fixed-bed reactors. This study leads to the BIOSTYR © support material which has been extensively deployed in VEOLIA wastewater treatment plants[1].

Finally, MELiSSA has started a collaboration with Eawag and Vuna on nitrification-based systems for nutrient recovery from source separated urine.

EDUCATION AND COMMUNICATION

NITRIFICATION has received frequent coverage in science communication fora, including appearance on television interviews, documentaries, newspapers, magazines, …

The actors are also highly welcomed guests to inspire the general audience, ranging over primary and secondary school students to higher education and working professionals. Numerous technologists and scientists were trained in this area, in the framework of the MSc and/or PhD studies, and a significant body of scientific publications is approved in peer-reviewed high-quality journals, on key aspects of the technology, microbiology, modelling, and its integration.