Modelling & Control

Academic research

Presented as the Ultimate objective of any recycling system, the elaboration and design of circular system bring challenges, which can be summarized:

- by nature, potentially unstable

- require high efficiency of all subsystems

- can only be justified after a large number of successful cycles.

These leads directly to the needs of a very elaborated and detailed characterization of all processes in static, dynamic modes, in optimal and degraded modes.

Almost any circular system is based on the assembly of interacting processes.

The nature and the respective dynamics of these processes are so diverse that they cannot operate successfully in stand-alone operation without control. A deterministic control is therefore a prerequisite of robust performance.

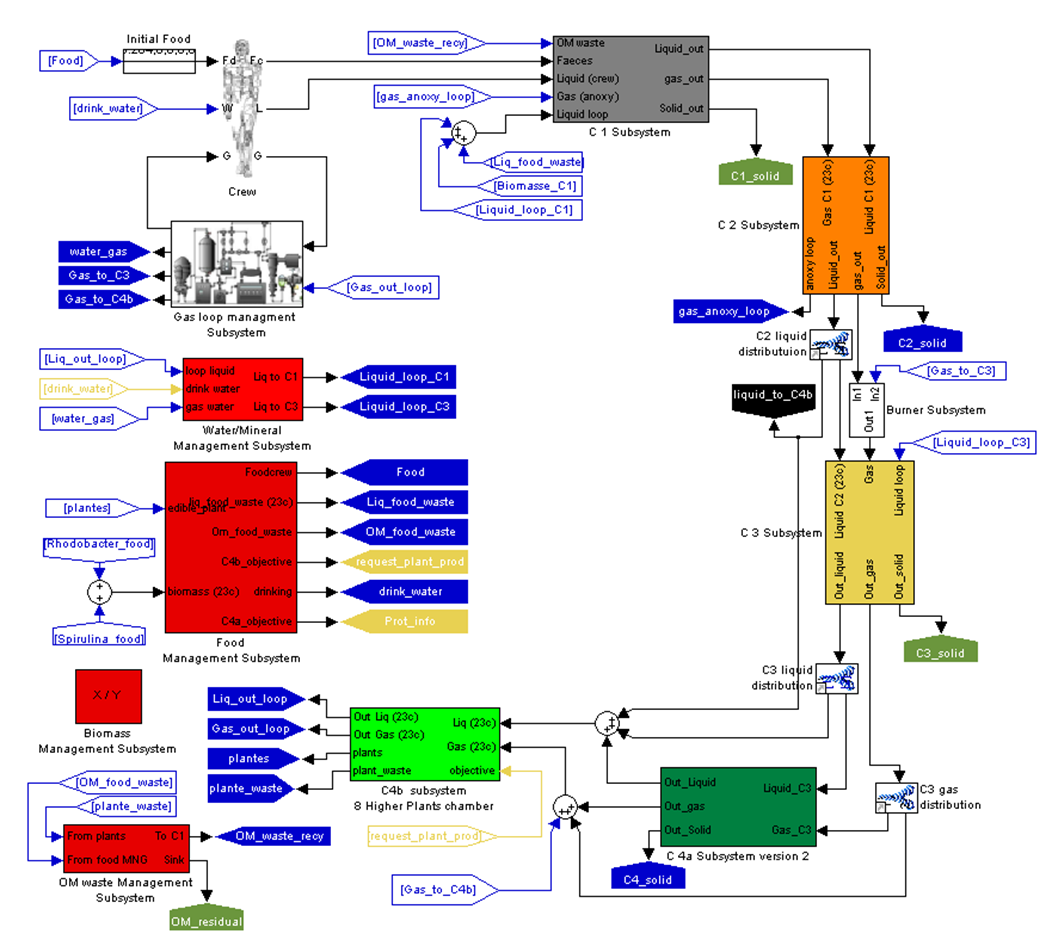

This includes at the prime level, the triptych: (i) measurement by reliable sensors, (ii) scheme of control and (iii) regulation. The mathematical deterministic modeling and simulation of the interacting parts of the system materialize the brain-level of the system.

Since the early days, of MELiSSA project and probably due to its father origin (i.e. Claude Chipaux, a MATRA-Airbus engineer), these challenges were perceived and many efforts has been taken in these directions, they are:

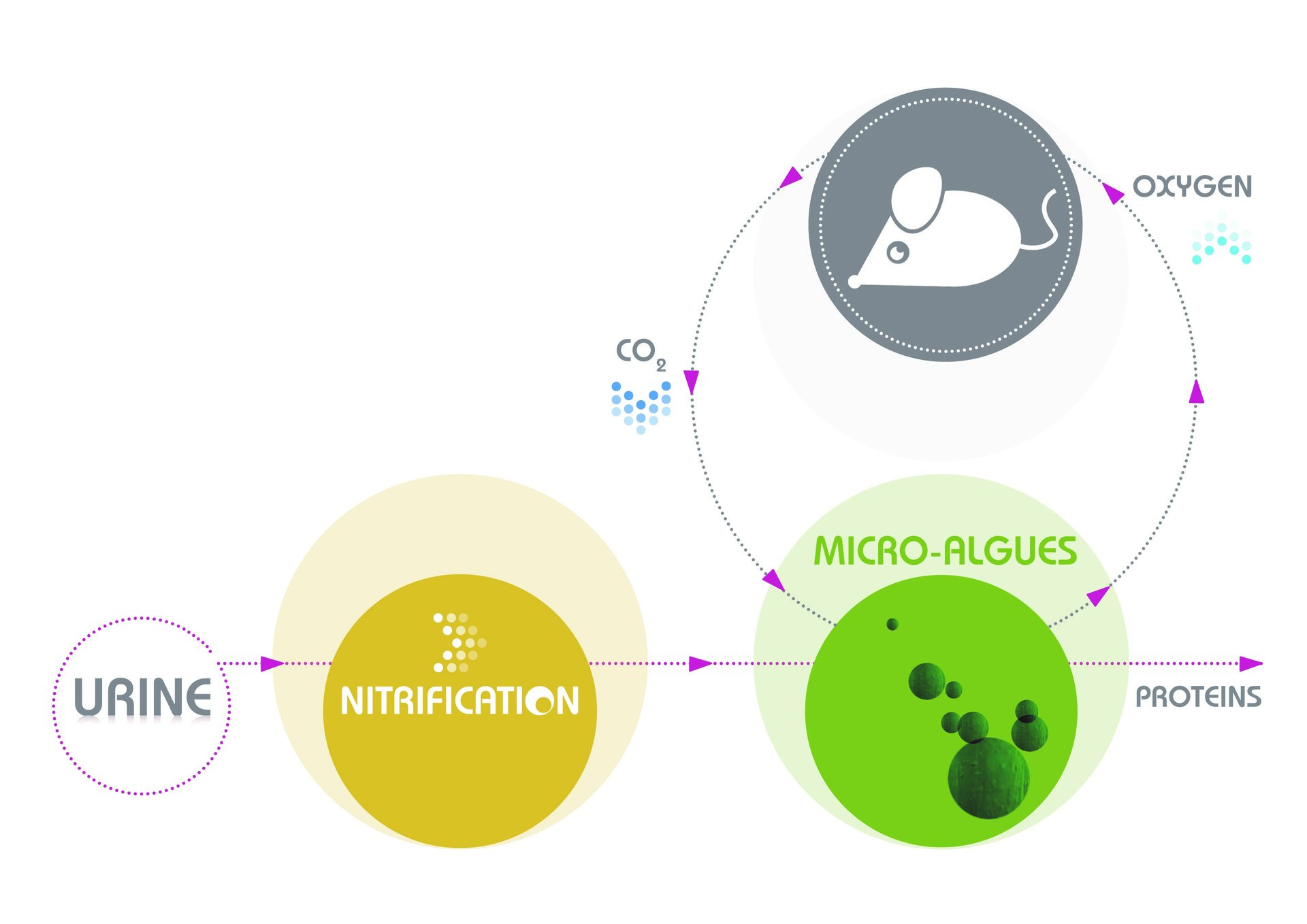

- Intensive characterization all processes at the level of the main chemical elements (C, H, N, O, S, P, ...)

- Mechanistic modelling and simulation

- Predictive control law

- System engineering approach.

Flight experiments

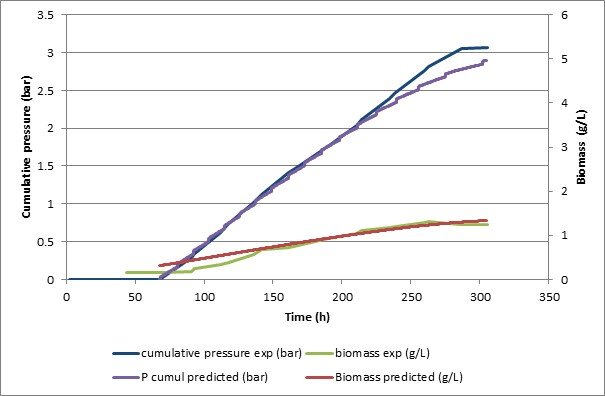

System tools and are certainly not the most affected by space environment; however, it is important to validate the engineering performance in a more realistic environment. As an example, the ARTEMISS flight experiment has allowed to demonstrate the excellent prediction of the CO2 to oxygen conversion on board the International Space Station.

Ground demonstration activity

Nowadays, subject to all lot of interest, there is surprisingly a very limited number of circular systems in demonstration.

Within the MELiSSA Pilot plant, the integration of all the systemic approach is progressively integrated and demonstrated over months. This MELiSSA loop demonstration start from the gas recycling (Coe to Oxygen), which is the highest dynamic and progressively integrate the MELiSSA processes upwards.

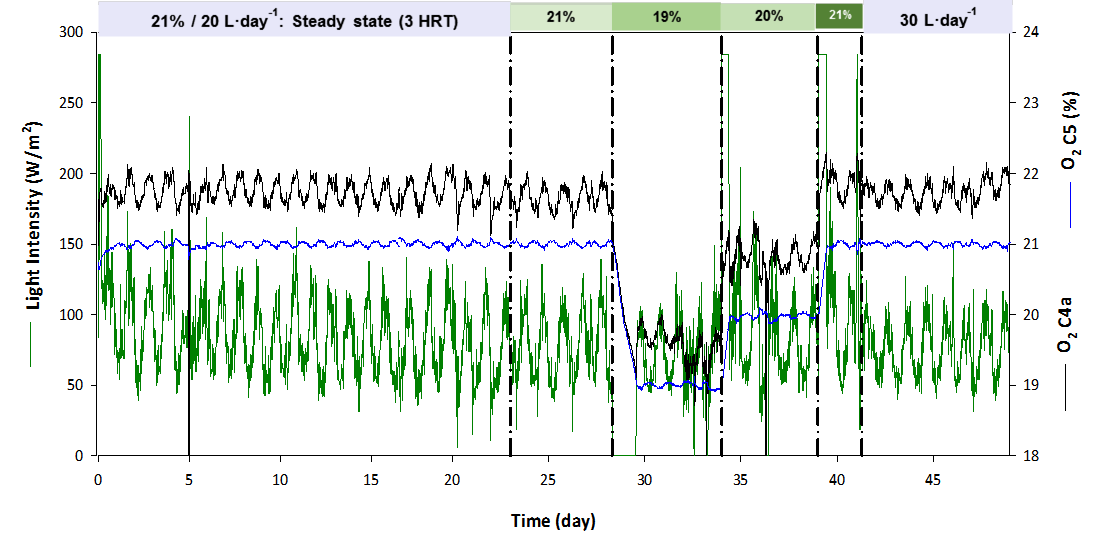

The high control strategy of MELiSSA already allows to connect 3 compartments in continuous mode and to recycle CO2 and Urine to produce oxygen. The control scheme is presented in Picture X, and figure 1 presents the controlled oxygen concentration in the rat habitat for 4 different set points ( 21, 19, 20, 21 %).

Terrestrial applications

The systemic approach developed within MELiSSA program is the main baseline of the tool-based methodology PhiSystem, a modeling tool for design and evaluation of complex systems.

It is now commonly used in terrestrial applications and in particular in the French automotive market for the control design of a vehicle energy system and leads to the improvement of quality, performance and flexibility.

PhiSystem is currently being deployed in autonomous vehicles and for the global resources management of circular systems, as smart building and eco-district.

Education and communication

Due to its extremely high degree and constraints, as well as its visibility, MELiSSA project is often presented as the ultimate circular system, and therefore today an excellent academic tool.

Over the years, a very large number of talks and MELiSSA lectures has been performed leading to a strong European motivation, PhDs, and associated publications.